Quality Control

Quality Assurance

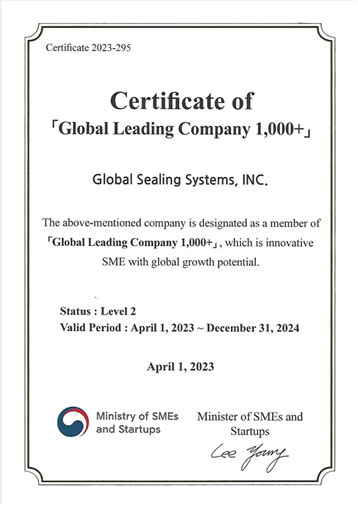

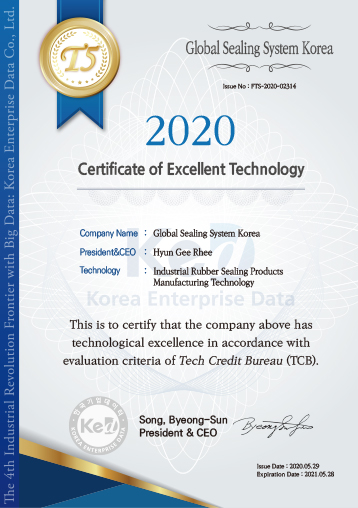

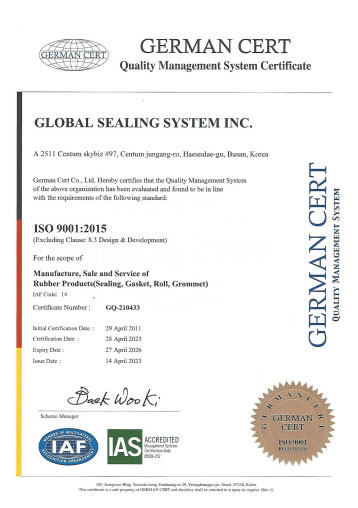

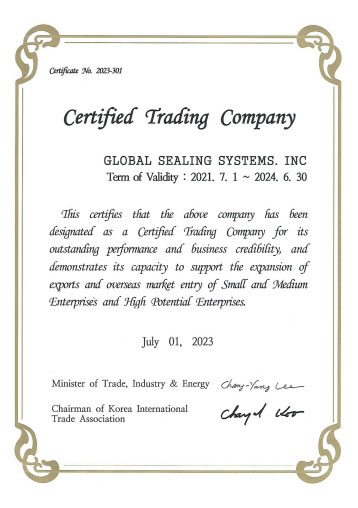

Throughout a product's lifetime there must be regular quality reviews to reduce costs and to improve future design. Small modifications can often produce further savings in both the manufacturing stages of the components and on customers' assembly lines. Reviews should look closely at manufacturing data to seek areas where costs can be reduced, production simplified, and quality and reliability increased. All parts produced by GSS's sister factories have established and implemented a quality improvement program employing ISO/QS 9000. PPAP's documentations available. This program has effectively helped us reduce costs, increase efficiency, and strengthen our competitive position. In pursuit of quality products that meet or exceed every industry standard, GSS maintains a full complement of modern facilities for process control and quality assurance testing. If potentially incapable processes are to be used, design revisions should be considered. Designs should then be passed through FMEA for confirmation and control / monitoring points generated. The platform for quality is now established. Complete lot traceability and test data is fully documented and available. Total quality is guaranteed.